New enabling technologies from Automate 2025

DETROIT — With more than 40,000 attendees and 800 exhibitors, Automate 2025 this week was a prime place to see and learn about the latest industrial automation.

With the event came an avalanche of announcements about new products, partnerships, and applications. Here are some of the latest enabling technologies for manufacturing and logistics as part of our ongoing Automate coverage.

Cattron unveils XBMCU multi-interface machine control unit

Cattron, a developer of radio remote controls, engine and generator control panels, and cloud-based monitoring technologies, showed its XBMCU Multi-Interface Machine Control Unit at Automate. The Warren, Ohio-based company said the controller offers integration into PLCs (programmable logic controllers) through multiple serial protocols.

The XBMCU is designed to with Cattron’s Safe-D-Stop wireless emergency stop, most CattronControl radio remote transmitters, and the latest generation of Remtron wireless devices.

According to Cattron, the XBMCU provides robust capability to support machine-to-machine functionality in both directions with high data volume. It features dual CANbus interfaces supporting J1939, CAN FD, CANopen, and CANopen Safety protocols, along with lab-certified PROFINET communications for reliable, real-time data handling with Class C Conformance.

The XBMCU is a compact control unit designed for mobile machines, industrial automation, robotics, and machine-to-machine control. Source: Cattron

Schneider Electric introduces industrial copilot

Also at Automate 2025, Schneider Electric introduced its industrial co-pilot, developed in collaboration with Microsoft. The company designed it to boost productivity and enhance workforce efficiency.

The system integrates Microsoft Azure AI Foundry with Schneider Electric’s secure industrial automation. Eliminating repetitive tasks, this generative AI-powered assistant allows users to collaborate, supports simplification of application development, delivers efficiency gains, and brings quality solutions to market faster, asserted the partners.

The copilot will be available within Schneider’s newly launched EcoStruxure Automation Expert, a unified automation environment. It integrates across hardware and software, enhancing collaboration between copilots, operators, and engineers by incorporating real-time data access.

This is crucial for providing accurate recommendations, predictive maintenance, and immediate troubleshooting, said Rueil-Malmaison, France-based Schneider Electric.

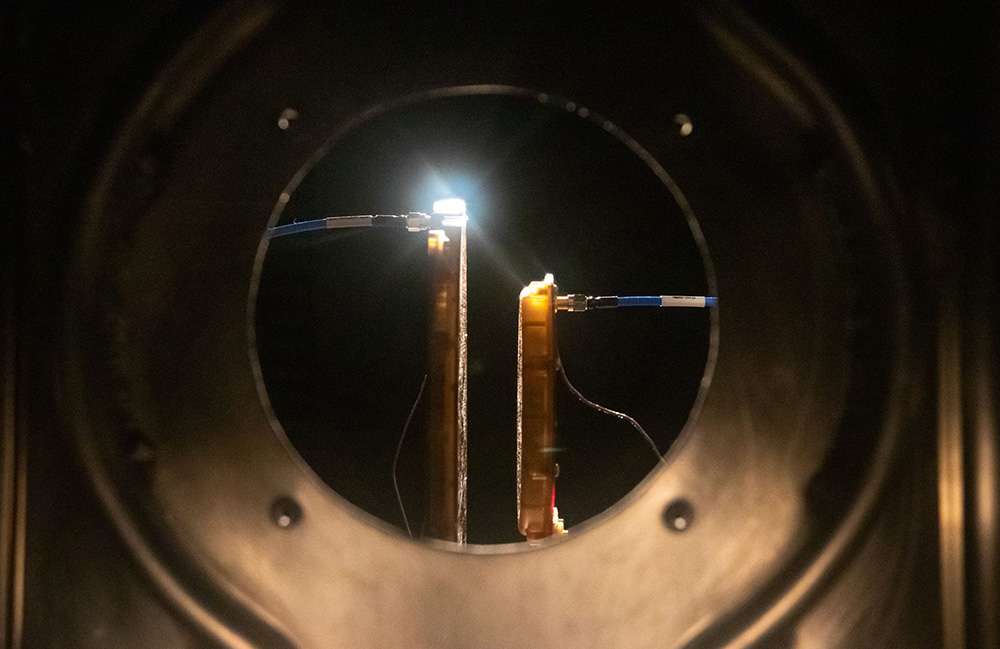

Novarc shows new NovAI vision system for welding

Novarc Technologies Inc., a full-stack AI robotics company specializing in the design and manufacturing of automated welding systems, this week launched NovAI. This AI-powered system brings both vision and real-time adaptation to articulated robotic and mechanized welding. NovAI Capture, NovAI Control, NovAI Autonomy, and NovSync were among the technologies the North Vancouver, British Columbia-based company launched this week at Automate.

NovAI Capture brings machine vision into the robotic welding process. This gives welders real-time visibility into the weld pool and automatically records every weld with full parameter data, said Novarc. NovAI Capture turns welding from a black box into a fully traceable, optimized process, driving higher quality welds with lower risk, it claimed.

NovAI Control combines human expertise with robotic welding to handle complex welds more easily and accurately, explained Novarc. This reduces the need for precise fit-up and heavy fixturing. Operators can adjust weld paths and process parameters in real time as they watch the weld pool through machine vision, dramatically minimizing the risk of costly defects due to fit-up variations.

Novarc added that its systems can eliminate over-welding, pre-scanning, and touch-ups.

Finally, NovAI Autonomy lets robots see and adapt like expert welders, eliminating the need for pre-scanning, manual adjustments, and rework. This speeds up manufacturing time and increases the quality of the welds.

The AI-powered system automatically adapts welds in real-time to fit-up variations, tacks, and seam distortions, so no operator input is required, stated Novarc at Automate 2025.

Rollon expands TH actuator range with new size 200

In addition, Rollon, a developer of linear motion systems, launched the new size 200 for its high-precision TH ball screw-driven linear actuator. This addition expands its existing range and offers new opportunities for designers and engineers requiring greater performance and flexibility in demanding applications.

The TH actuator series has a compact design and provides positioning accuracy, said Rollon. It has a repeatability within ±5 μm, making it suitable for industrial automation, packaging, and robotics.

With the introduction of the size 200, the company said it is responding to growing market demand for actuators capable of handling higher loads and delivering longer strokes.

The TH actuator uses ball screws for thrust-force transmission, available in various precision classes and lead options to meet application-specific needs.

The linear motion system is guided by two or four preloaded recirculating ball-bearing blocks with ball retainer technology. These run on parallel rails for optimal rigidity and smooth movement.

The TH series is available in both single and double carriage configurations, allowing for versatile load management, said Rollon.

The TH ball screw-driven linear actuator is designed to deliver exceptional precision and repeatability in linear motion. | Source: Rollon

Kistler shows maXYmos BL 5867C, AkvisIO 7.0 at Automate 2025

Kistler spotlighted its new maXYmos product, a process monitoring system that uses sensor technology to visualize and quantify production data in real time, and its AkvisIO 7.0, a modular system tailored for plastics injection.

The Winterthur, Switzerland-based company said maXYmos allows manufacturers to spot defects immediately, stop production instantly, and eliminate waste and bad products before they multiply. The newest product in the maXYmos family enhances process monitoring and quality assessment with new features designed for a large application range. These include:

A larger capacitive display

Improved usability and flexibility in terms of local and remote access management and various hardware designs

A new USB port for backup/restore and barcode reader support

New licenses for access protection (also via LDAP function)

Industrial Internet of Things (IIoT) connectivity via OPC Unified Architecture

Integrated process control

The AkvisIO 7.0, on the other hand, enables comprehensive data collection and quality control throughout molding and assembly. This system helps ensure that every joint is the same depth and strength, supporting 100% inspection and zero-waste manufacturing goals, the company said.

Kistler’s enhanced process data management software for injection molding, AkvisIO 7.0, is designed to consolidate, document, and analyze quality data from various sources, including ComoNeo.

Improved usability, new visualization features, and expanded connectivity via OPC UA and Euromap 77 enable manufacturers to monitor multicomponent processes, track long-term trends, and optimize production efficiency with greater precision, it said.

Now accepting session submissions!

Geisel Software debuts Symage synthetic data platform

Geisel Software, a provider of 3D photorealistic synthetic image data, debuted Symage at Automate 2025. The company said the Symage concept was born from Geisel’s collaboration with NASA on synthetic data for Mars exploration, where traditional data collection is impossible.

This work underscored the value of synthetic data in training AI models when real-world data is limited—an insight that led to the creation of Symage as a scalable platform for machine vision in automation, explained CEO Brian Geisel.

Unlike generative AI data, Symage relies on physics-based simulation to produce custom 3D environments with pixel-perfect labeling. This approach ensures models are trained under realistic and precisely controlled conditions, eliminating data scarcity, reducing bias, and dramatically accelerating AI workflows.

MachineMetrics launches AI-driven monitoring tool

MachineMetrics, a global developer of production intelligence systems for discrete manufacturers, this week launched its predictive tool monitoring system. With MachineMetrics’ latest release, manufacturers can leverage AI to quickly diagnose, predict, and avoid failures on machine tools, the company claimed.

Manually identifying when tooling will fail is nearly impossible, which prompts manufacturers to either replace tooling and components too early or simply run machines to failure. These strategies result in wasted tool life, scrap, catastrophic breakdowns, and unplanned downtime.

MachineMetrics Tool Anomaly Detection detects anomalous machining activity — like shifts in load, torque, and spindle speed — to predict impending failures, maximize tool life, and eliminate quality issues and downtime.

The Easthampton, Mass.-based company’s software captures high-frequency data from the machine control without the need for invasive sensors. Next, proprietary algorithms detect anomaly events on the machine. Then, workflows immediately notify the right person or automatically stop the machine when triggered.

Follow our ongoing coverage of Automate 2025.

Responses